Procurement Policy

TBK conducts global production and procurement activities both in Japan and overseas.

In these global operations, we offer fair opportunities to all companies, domestic and international, and procure high-quality parts that meet our requirements through impartial evaluation.

Our procurement activities are based on this fundamental principle. We comply with international and domestic laws as well as social norms, and strive to build mutually cooperative and trusting relationships with our suppliers while pursuing optimal quality and cost.

Furthermore, we actively promote initiatives to fulfill our social responsibilities—such as global environmental conservation—with the cooperation of our suppliers.

Green Procurement Guidelines

To minimize our environmental impact as much as possible, we prioritize the procurement of materials and parts that are environmentally friendly. Our green procurement policy aims to reduce environmental impact not only through our production activities and products, but also in the procurement of materials and parts.

This policy applies to all products, materials, and components procured throughout the TBK Group. Environmental impact must be considered across the entire product life cycle—from procurement and processing/assembly to transportation, usage, and disposal.

This effort cannot be achieved by our company alone; the cooperation of our suppliers is essential. As the importance of addressing climate change continues to grow, we intend to further enhance our environmental efforts in close collaboration with our partners.

We sincerely appreciate the continued support and cooperation of our suppliers in our sustainability initiatives and look forward to even stronger partnerships going forward.

Supplier Communication Activities

To strengthen trust and improve communication with our suppliers, TBK holds annual policy

briefings.

These sessions clearly communicate our management and procurement policies, and cover a wide range of topics including sustainability initiatives and requests for BCP (Business Continuity Planning) cooperation. We also recognize and commend outstanding suppliers during these events.

In addition, we host an annual production briefing session aimed at further enhancing quality across our supply chain.

Scene from the Annual Policy Briefing

Scene from the Annual Policy Briefing| April | May | June | July | Aug. | Sept. | Oct. | Nov. | Dec. | Jan. | Feb. | Mar. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Policy Briefing session | ● | |||||||||||

| Production Briefing Session | ● | |||||||||||

| TBK Partners Meeting | ● | ● | ● | ● | ● | |||||||

| Awards for Outstanding & Cooperative Partners | ● |

Implementation of Supplier Assessments

We conduct comprehensive evaluations of our suppliers to verify the status of their initiatives

and identify potential risks and opportunities. For suppliers who do not meet our internal standards, we develop corrective action plans and provide guidance to encourage improvements.

| Category | Evaluation Criteria (Examples) |

|---|---|

| Q:Quality | Efforts to improve and enhance quality |

| C:Cost | Initiatives related to value analysis and cost reduction proposals |

| D:Delivery | Efforts to maintain stable supply |

| M:Management | Initiatives related to business continuity, such as succession planning |

| S:Supportiveness | Responsiveness to customer requirements and our company’s surveys or requests |

| E:Environment | Efforts to acquire environmental certifications and related initiatives |

Training for Purchasing Personnel

To ensure the smooth execution of procurement activities, we regularly provide training for employees assigned to the Purchasing Department. The training content varies according to each employee’s career stage and covers topics such as essential knowledge and skills for purchasing operations, risk management in procurement, and leadership in global sourcing. In addition, we are expanding the scope of our initiatives from green procurement to clean procurement.

The following flowchart outlines the basic procedure for initiating transactions. Please note that actual steps may vary slightly depending on the case.

- Step

- 1.Proposal for Business Transaction

- 2.Request for Quotation

- 3. Quotation Evaluation / Adoption Review

- 4.Order for Sample Products

- 5.Quality Evaluation / Supplier Visit / Production Process Audit

- Supplier

- Submit a proposal via the contact form

- Prepare quotation documents

- Submit quotation documents, make a presentation

- Produce and submit sample products

- submission of samples

- TBK

- Evaluate and review the proposal

- Conduct preliminary review and request submission of quotation documents based on evaluation of quality, technical capabilities, cost, delivery time, management status, and stability

- Evaluate the quotation and consider adoption

- Place sample order

- Conduct quality and technical assessments, visit supplier, and inspect production processes

- 6.Negotiation of Transaction Terms

- 7.Contract Signing

- 8.Start of Business Transactions

- Negotiate transaction terms

- Sign the contract

- Begin business transactions

Quality Policy

To manufacture and deliver safe, highly reliable products to our customers.

In order to realize this fundamental philosophy, we commit to the following actions:

- We will consistently supply products that meet customer requirements and comply with applicable laws and regulations, while striving to improve the "quality" of both our operations and products, thereby gaining customer satisfaction and trust.

- To achieve our quality policy, we will establish quality objectives, evaluate our activities and results in accordance with defined rules, and continuously improve the effectiveness of our quality management system.

- We will regularly review the appropriateness of our quality policy and assess the need for revisions

Quality Management System

Quality Management Structure As part of its quality improvement framework, the TBK Group holds two monthly meetings: the Company-wide Quality Meeting and the Factory Quality Review Meeting.

The Company-wide Quality Meeting is chaired by the Head of Quality Management and includes executives at the department head level or higher from subsidiaries. It is designed to review product quality conditions and the effectiveness of the quality management system for the President of TBK, who holds ultimate management responsibility. These meetings facilitate cross-departmental information sharing on quality issues and allow for the formulation of solutions. The outcomes, including directives from top management, are shared across the entire TBK Group to promote improvement.

The Factory Quality Review Meeting consists of plant managers, section chiefs, and quality department members. The meeting addresses quality issues in manufacturing processes, postshipment problems, and material defects including those from the supply chain. It aims to implement countermeasures and drive continuous quality improvements.

These meeting bodies embody the company-wide quality initiatives and play a critical role in maximizing the effectiveness of the Group’s quality management system.

Quality Management System Certification

Since acquiring ISO 9001 (the international standard for quality assurance systems used by automakers) in 1999, the TBK Group now operates under the IATF 16949 standard. This enables the Group to maintain a production system capable of delivering high-quality, high-precision products both domestically and globally.

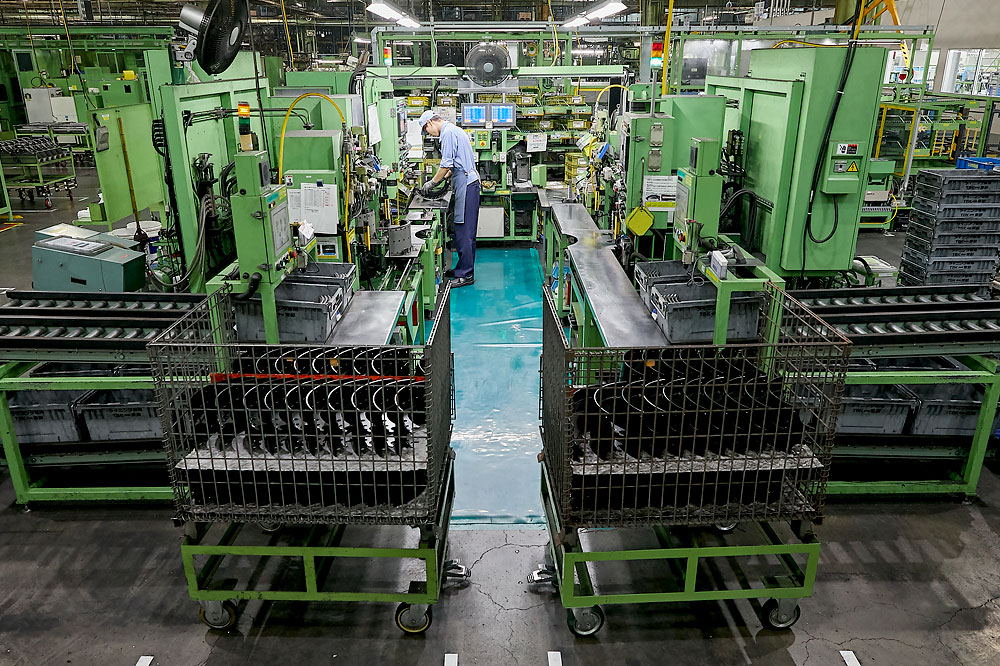

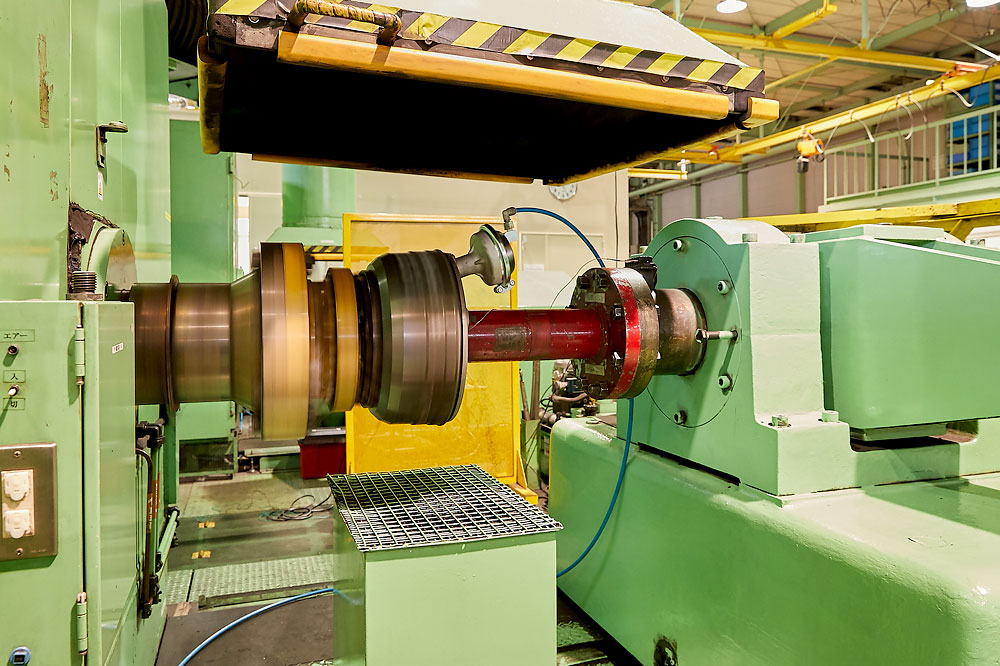

From TPS to NPS – Evolution in Manufacturing

TBK has joined the NPS (New Production System) Study Group, an organization supporting

Japanese manufacturing industries. Through active engagement in learning the latest production management methods and industry best practices, TBK continues to enhance its original production system to build a more flexible and efficient manufacturing structure.

While inheriting the TPS (TBK Production System) philosophy of “delivering the right products in the right quantities at the right time,” the Group minimizes lead times, inventory, and resource input across the supply chain — from raw material procurement to final sales.

With the NPS production system, TBK promotes a manufacturing approach that achieves higher quality and productivity by eliminating waste thoroughly, integrating Just-in-Time, automation with a human touch, and a respect-for-people philosophy at its core.

Lightweight SAW Brake Assembly Line

Lightweight SAW Brake Assembly Line Lightweight SAW Shoe Assembly Line

Lightweight SAW Shoe Assembly Line Synchronized Shoe Supply (Directly Connected to Brake Assembly Line)

Synchronized Shoe Supply (Directly Connected to Brake Assembly Line) Expander Convergence Checker

Expander Convergence Checker Automated Expander Sleeve Assembly Line

Automated Expander Sleeve Assembly Line Automated Water Pump Assembly Line

Automated Water Pump Assembly Line Oil Pump Function Checker

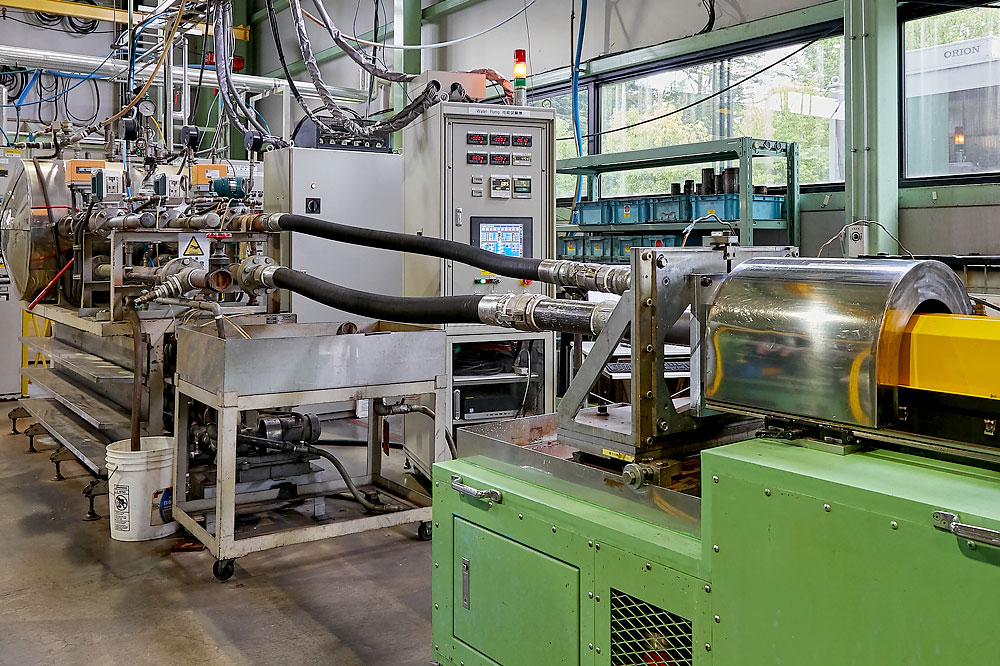

Oil Pump Function Checker Gas Soft Nitriding Furnace

Gas Soft Nitriding Furnace Gas Carburizing Furnace

Gas Carburizing Furnace| Category | Materiality | Evaluation Indicator | FY2024 Target |

|---|---|---|---|

| Social S |

Efforts to Improve and Enhance Quality |

|

Zero Target |

Research and Development

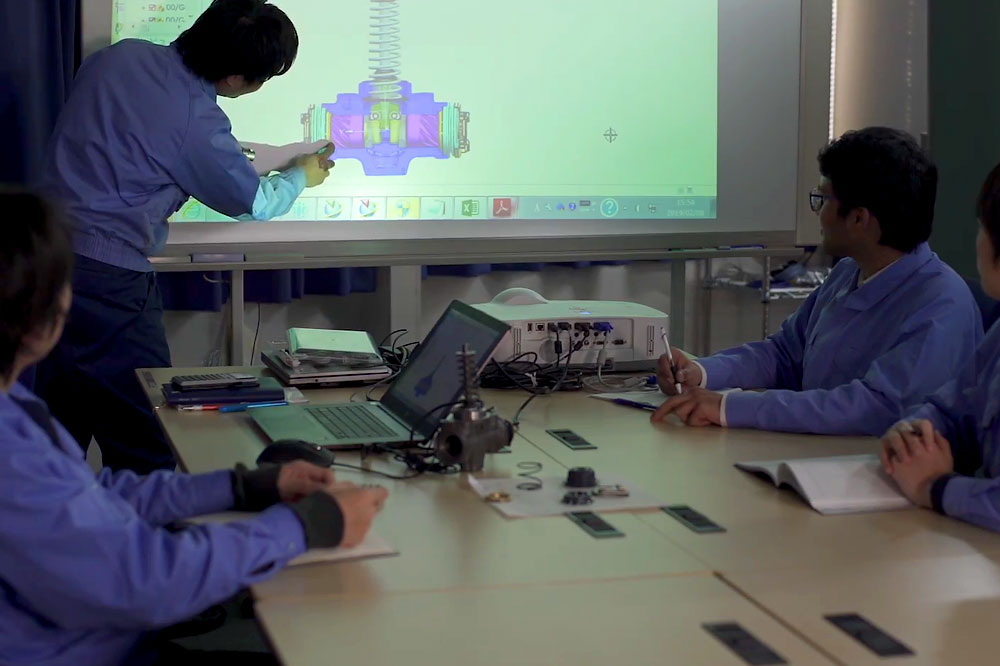

Planning / Development / Design

At TBK, we collaborate with vehicle and engine manufacturers from the early planning stages through to design and development. This cooperation contributes directly to reducing costs and shortening development timelines for our clients.

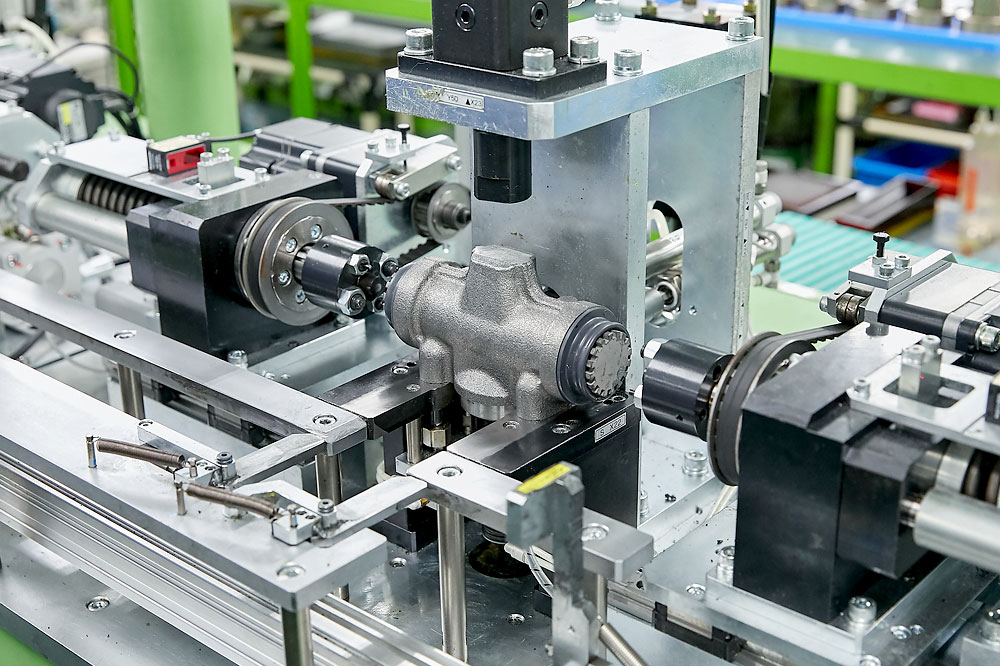

In the brake division, our key R&D themes include environmentally friendly brakes, linings, and pad materials. In the pump division, we pursue greater lightness, higher efficiency, and reduced noise while developing electronically controlled energy-saving pumps that operate with minimal energy to maximize engine performance—thereby supporting the development efforts of engine and vehicle manufacturers.

In the new product development division, we are promoting R&D to meet emerging application needs as part of our initiatives toward carbon neutrality. We are leveraging our accumulated mechanical water and oil pump technologies to realize mass production of electric pumps and are working on the development of thermal management systems for commercial vehicles centered around these technologies.

Furthermore, to improve production efficiency and reduce costs, we consistently apply a design philosophy that emphasizes standardization of parts and processes.

Development Scene

Development Scene R&D Activities

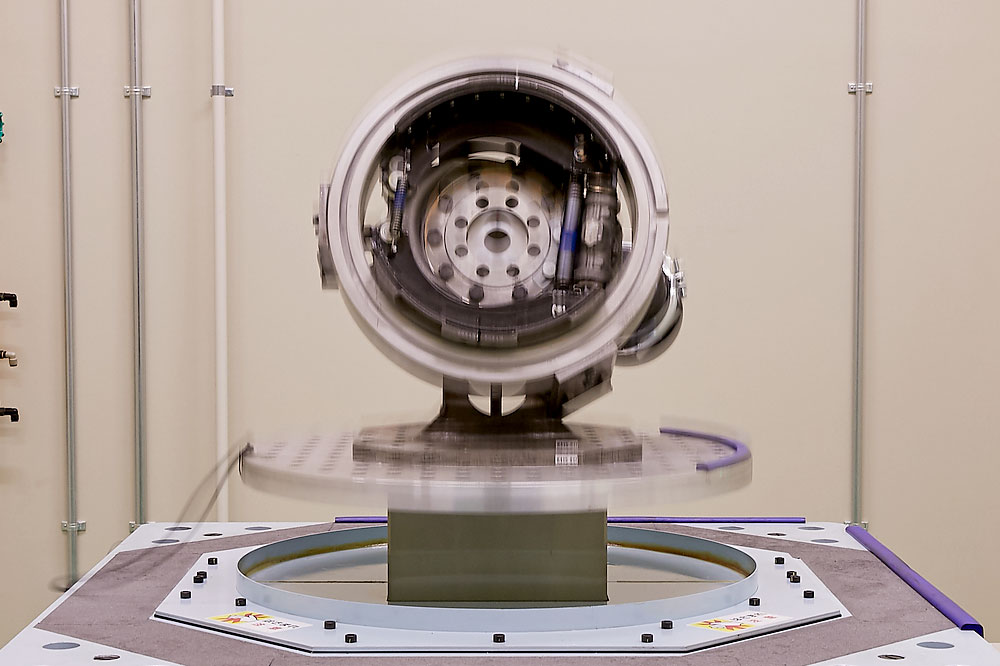

R&D ActivitiesBench Test

Before launching a new product to the market, we conduct rigorous performance and durability tests that simulate actual vehicle operation. In addition, we perform environmental tests—including temperature, humidity, water immersion, and vibration—to ensure product reliability

Brake Performance Test

Brake Performance Test(In this test, with dust cover attached)

Autonomous Driving Control Room

Autonomous Driving Control Room Water Pump Performance Test

Water Pump Performance Test Oil Pump Performance Test

Oil Pump Performance Test Vibration Durability Test

Vibration Durability TestVehicle Testing

In addition to a wide range of performance and durability tests conducted using bench testing equipment, we also perform extensive real-world vehicle testing. Our high-speed circuit allows us to conduct tests under diverse conditions, from low-speed to high-speed driving environments, ensuring comprehensive validation of product performance in actual vehicle operation.

Tokachi Proving Ground

Tokachi Proving GroundThe TBK Group implements a variety of training programs aimed at raising employee awareness of quality. From startup courses that teach the basics of quality standards to advanced courses for mid-level employees focused on continuous skill improvement, we provide customized education tailored to each organizational level, reinforcing the foundation of quality management.

【Key Initiatives】

- Quality Manual Education

Target:Team leaders and above

Purpose:Understanding TBK's QMS (Quality Management System) - In-house Measurement Skill Certification System

Target:Manufacturing operators

Purpose:Enhancing measurement skills - QC Certification Training (Level 3 & 2)

Target:Manufacturing team leaders, indirect departments

Purpose:Acquiring appropriate usage of statistical tools and understanding quality control - Visual Inspection Skills Improvement Using Limit Samples

Target:Manufacturing operators, quality control workers

Purpose: Preventing the outflow of defective products - Correspondence Education

Target:All employees

Purpose:Qualification improvement and self-development - Internal Auditor Training

Target:Departments involved in QMS, manufacturing processes, and product audits

Purpose:Enhancing TBK's QMS - Training for Certified Operators of Critical Safety Parts

Target:Workers handling critical safety components

Purpose: Ensuring quality assurance for products critical to human life - Training for Operators of Special Processes

Target:Workers engaged in special processes

Purpose: Ensuring the quality of products whose defects cannot be detected by appearance and only after use

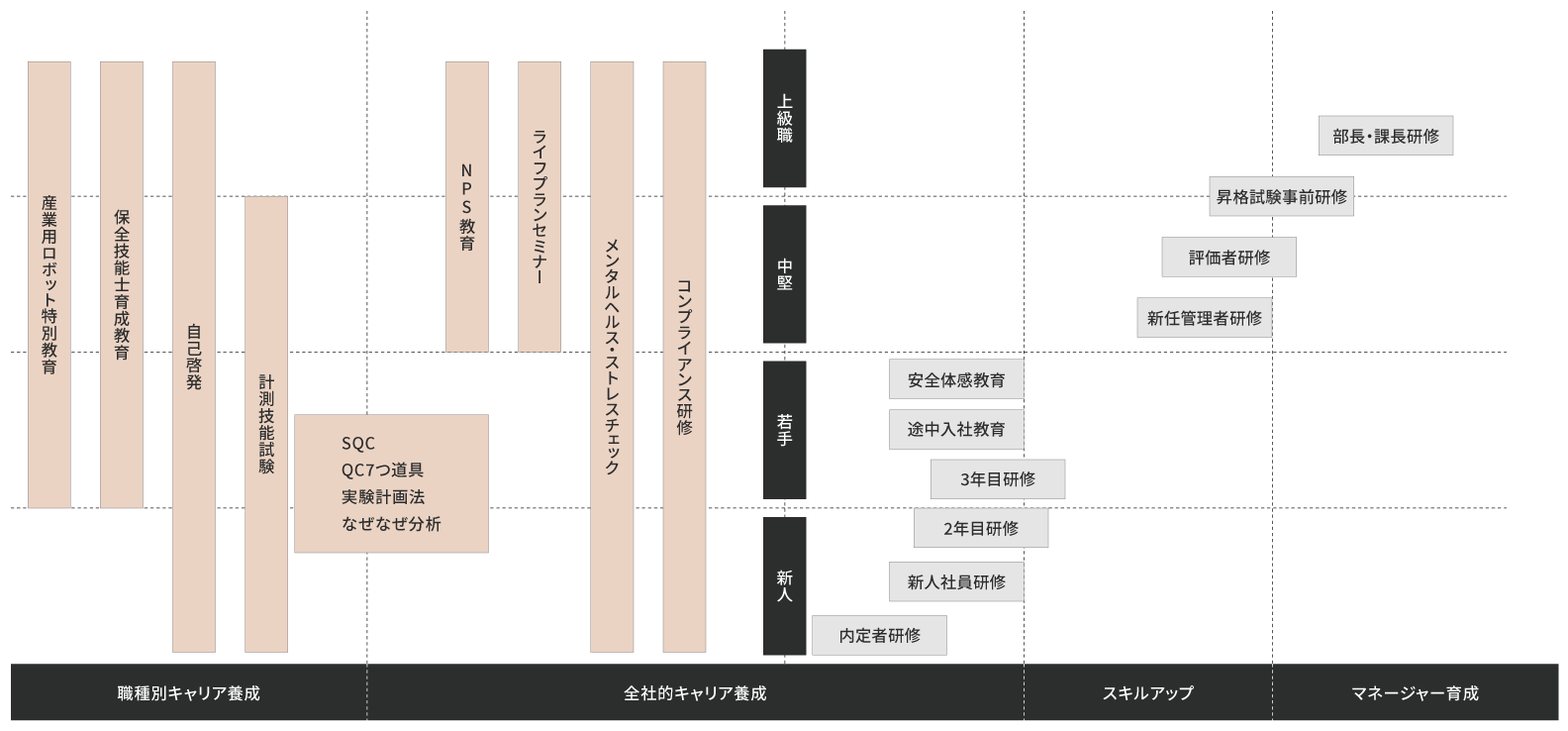

Human Resource Development Policy

In order to enhance corporate value amid a constantly changing external environment, it is essential for employees with diverse values to demonstrate initiative, creativity, and a sense of responsibility as they work to realize our management vision. To this end, we have developed an educational framework tailored to the skills required at each career level, aiming to establish a system where each individual can fully demonstrate their capabilities.

Ideal TBK Personnel Profile

Individuals who possess:

● Initiative

● Creativity

● A sense of responsibility

● Strong execution capabilities

In line with our human resource development policy, TBK has established a system that supports employee growth. Centered on the General Affairs Department and training personnel,

we plan and implement training programs to enhance the skills and knowledge of every employee, while also focusing on fostering globally minded talent. At each production site, we are also committed to nurturing the next generation of talent through workplace education and support for technical intern trainees. By ensuring close coordination between headquarters and each plant, we strive to provide diverse growth opportunities and create an environment

where all employees can realize their full potential.

| Policy | Strategic Initiatives | Indicator | FY2022 | FY2024 Target |

|---|---|---|---|---|

| Planned development for career formation | Implementation of systematic, tiered training | Participation rate of eligible young employees | 100% | 100% |

| Participation rate of management personnel | - | 100% | ||

| Development of global talent | Promotion of inter-company personnel exchange | Number of personnel transferred within the group | 1 person | 8 persons |

Planned Development for Career Formation

Aiming to nurture individuals with autonomy, creativity, a strong sense of responsibility, and execution capabilities, we clearly define the skills required at each career stage, from junior employees to management. We implement planned and systematic training programs to support the acquisition of these skills.

Additionally, to foster the next generation of leaders, we actively implement personnel rotations and secondments to domestic and international group companies to provide diverse experiences and perspectives.

Through training programs, we also promote communication across departments and sites within the group, aiming to vitalize the organization and cultivate a corporate culture that embraces new challenges.

Global Talent Development

Our group promotes global human resource development and the utilization of diverse talent through domestic and international group companies.

Specific Initiatives Include:

- Establishing a joint research and development system among Japan, Thailand, and India to enhance the group’s overall development capabilities

- Promoting the global deployment of diverse talent through inter-site personnel exchanges, creating an environment that encourages innovation through the unique strengths of employees with varied perspectives (overseas trainee program)

- Holding global HR meetings and formulating strategies for talent exchange across locations

- Introducing group factories through online factory tours and incorporating initiatives and ideas from other sites

- Developing training programs in Japan for overseas engineers to support their professional development

Training and Education Programs

Education & Training Map

Our Approach to Human Resource Diversity

At our company, we respect the diversity of our human resources and aim to deepen the understanding of diversity across the entire Group. In accordance with the "Act on Promotion of Women's Participation and Advancement in the Workplace," we are committed to creating a work environment that respects diverse lifestyles and values—including childcare and nursing care responsibilities—regardless of gender or other attributes, enabling employees to work for the long term.

| Category | Materiality | Evaluation Indicator | FY2024 Target |

|---|---|---|---|

| Social S |

Recruitment and Utilization of Diverse Human Resources | Percentage of Women in Management | Positions: 15% |

Support for Balancing Childcare and Nursing Care

We have established childcare and nursing care leave systems to foster a corporate culture where all employees, regardless of gender, can utilize these systems.

Proactive Hiring of Women

We actively disclose information related to the success of female employees to attract more applicants.

Promotion of Women in the Workplace

We encourage the promotion and advancement of female employees and work to eliminate

wage disparities.

Initiatives for the Utilization of Diverse Human Resources

We are working to create an environment where diverse personnel can fully demonstrate their abilities.

To promote the active participation of senior employees, we have introduced a “Post-Retirement Reemployment” system for those aged 60 and over. This system provides flexible working arrangements based on individual career plans, allowing seniors to continue contributing.

For foreign employees, we offer “in-house Japanese language classes,” which help them learn communication methods and workplace guidance necessary for smoother daily operations and foster mutual understanding across cultures.

We are also actively promoting the employment of people with disabilities and are developing workplace environments tailored to their individual needs. Through such efforts, we aim to provide a comfortable working environment and enhance organizational diversity.

We will continue to promote a work environment where people from diverse backgrounds can thrive and perform to their full potential.

Workplace Environment Policy

To create a fulfilling workplace, we are committed to improving employee health, promoting work-life balance, and enhancing employee satisfaction.

| Policy | Strategic Initiative | Indicator | FY2022 | FY2023 | FY2024 Target |

|---|---|---|---|---|---|

| Diversity of Human Resources | Creating a Fulfilling Workplace | Annual Paid Leave Utilization Rate(Figures in parentheses indicate average days taken) | 81.6% (12.7 days) |

75.1% (14.0 days) |

80.0% or higher (14.0 days) |

| Turnover Rate Within 3 Years of Employment | 28.6% | 19.5% | 25.0% or lower |

Implementation of Employee Awareness Surveys

We regularly conduct employee awareness surveys. Based on the results of these questionnaires, we identify issues and reflect them in future measures and initiatives.

Basic Approach to Occupational Health and Safety

We recognize the safety and health of our employees as a critical priority. We are committed to thorough occupational health and safety management, accident prevention, and continuous improvement of the workplace environment.

Occupational Health and Safety Promotion System

Our company promotes occupational health and safety management through the “Occupational Health, Safety, and Environment Committee.”

This committee is composed of representatives from both management and labor, an occupational health nurse, and an industrial physician, and meets monthly at each site.

Key agenda items include safety patrols, incident reports, interviews with the occupational health nurse, and sharing of health and safety information from other companies.

| Category | Materiality | Evaluation Indicator | FY2024 Target |

|---|---|---|---|

| Social S |

Maintenance and Improvement of Product Quality & Occupational Safety | Number of Serious Accidents | 0 (Zero Incident) |

Risk Assessment for Occupational Health and Safety

We conduct risk assessments related to occupational health and safety. Through these assessments, we identify potential safety and health risks and implement multifaceted measures such as education, training, and emergency response planning. Our goal is to ensure a safe workplace environment for all employees.

Implementation of Safety Experience Training

New employees are provided with safety experience training using actual factory equipment

to help them recognize potential hazards. This hands-on approach raises awareness and strengthens their understanding of workplace safety.

Deployment of Occupational Health Nurses

We have assigned occupational health nurses to our Head Office, Fukushima Plant, and Tsuruoka Plant. These professionals provide health consultations, conduct interviews upon request, and share health-related information, all aimed at creating a workplace where employees can work with peace of mind.

Health Management Declaration

Our long-term goal is to “contribute to society through sustainable growth.” We believe that

promoting employee health and creating a work environment where everyone can fully realize their potential are essential to invigorating the organization and achieving sustainable growth. To enrich the lives of our employees and ensure continuous corporate development, we position the promotion of employee health as a key management strategy and are committed to supporting both physical and mental well-being.

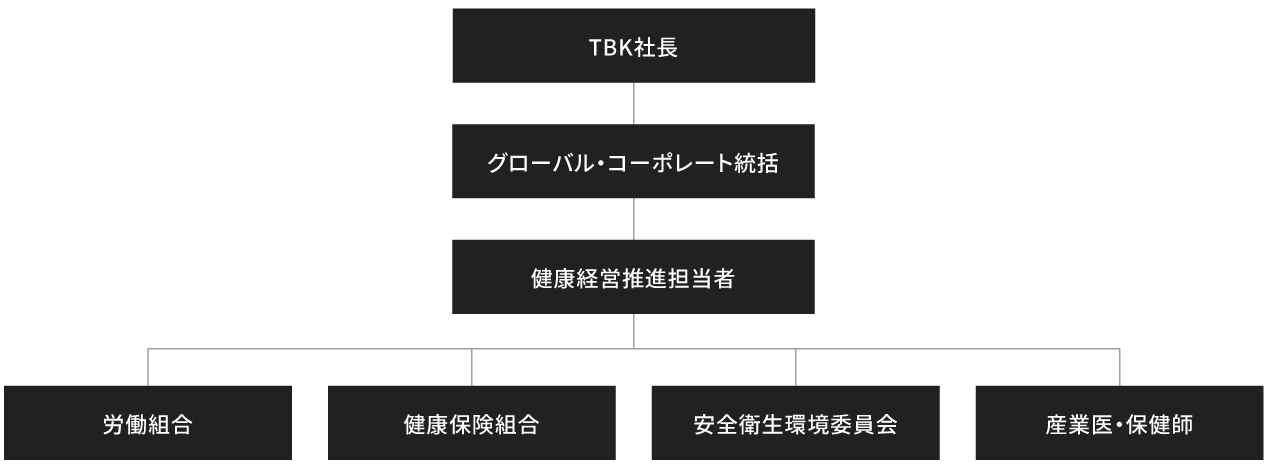

Health Management Promotion Framework

Our health management initiatives are led by the President of TBK, with designated health management officers playing a central role in driving these efforts.

| Category | Materiality | Evaluation Indicator | FY2024 Target |

|---|---|---|---|

| Social |

S | Creating a Fulfilling Workplace | Promotion of Health Management |

Efforts to Maintain Employee Health

We are actively engaged in maintaining employee health through the implementation of regular health checkups.

Key Focus Areas for Health Checkups

- Ensuring 100% participation in periodic health checkups by thoroughly following up with employees who have not yet received the exam

- Encouraging employees to undergo detailed examinations when necessary

- Promoting awareness of subsidy programs for optional medical tests

Certified as “2024 Health and Productivity Management Organization (Large Enterprise Category)”

We have been certified as a “2024 Health and Productivity Management Organization (LargeEnterprise Category)” under the certification program promoted by the Ministry of Economy,

Trade and Industry (METI) and the Nippon Kenko Kaigi.

Implementation of Stress Check

We conduct annual stress checks for all employees. Based on the results, employees are categorized into four risk levels. If an employee is identified as having a high stress risk, occupational health nurses provide interviews and support aimed at improving mental health. All results are handled in accordance with relevant laws and regulations, with full protection of employee privacy.

Interviews with Occupational Health Nurses

Our group is also committed to enhancing health management through occupational health

nurses. In accordance with our internal health interview rules, occupational health nurses assess workplace safety and hygiene conditions, and provide advice to managers regarding any identified issues.

Furthermore, employees facing mental health challenges receive personalized support, including individual counseling and return-to-work assistance. Through these initiatives, we aim to improve overall workplace health and create an environment where all employees can work with peace of mind.

Basic Approach to Social Contribution Activities

As a corporate citizen, our company is committed to the development of local communities and environmental conservation. Through these efforts, we aim to contribute to the realization of a sustainable society that grows in harmony with the community.

Registered as a Tsuruoka SDGs Promotion Partner

The Tsuruoka Plant has been registered as a “Tsuruoka SDGs Promotion Partner,” a program aimed at promoting the awareness and achievement of the SDGs in Tsuruoka City.

At networking events, topics such as “Challenges to be addressed in Tsuruoka,” “Creating a city where young people want to live,” “Fostering people who will support the local community,” and “Building a safe and secure town” have been discussed. Based on the insights gained from these exchanges, our company will further advance its initiatives toward achieving the SDGs in collaboration with the local community.

Participation in the Tsuruoka Zero Waste Operation

The Tsuruoka Plant took part in the "Tsuruoka Zero Waste Operation" in response to a call from the Waste Management Division of the Tsuruoka City Citizens’ Affairs Department. On May 30, known as “Zero Waste (530) Day,” employees participated in a beach clean-up activity at Yunohama Beach.

This initiative provided an opportunity to think about the issue of marine plastic waste while collecting litter along the coastline together with other local companies and organizations.

※ It is estimated that about 80% of marine plastic waste originates from land. Much of it comes from litter carelessly discarded on roads, garbage overflowing from collection points, or waste left behind during leisure activities—eventually washed into the sea by wind and rain.

Yunohama Beach, Tsuruoka City

Yunohama Beach, Tsuruoka City Marine Debris Collected on the Day

Marine Debris Collected on the DayTree Planting Activities

TBK INDIA PRIVATE LTD. has carried out tree planting activities over the past three years, planting approximately 164 trees within the factory premises to date.

Tree Planting Scene

Tree Planting SceneOpening of the Showroom at Fukushima No. 2 Plant

The Fukushima No. 2 Plant has opened a new showroom within its premises. With the theme of “Creating Sustainable Cities and Communities,” the showroom was established as a space to communicate the TBK Group’s corporate philosophy to all stakeholders, including the local community.

In addition to displays of products such as brakes, pumps, and engine assist systems, the exhibition area features a special collaboration zone with Tamakawa Village, symbolizing regional cooperation. Through this showroom, TBK aims to deepen engagement with stakeholders and further promote initiatives toward achieving the SDGs.

Brake Area

Brake Area Tamakawa Village Collaboration Area

Tamakawa Village Collaboration Area

TBK Group Human Rights Policy

Under our corporate philosophy of “creating products that please customers and contribute to society,” the TBK Group supports the safety and reliability of logistics by ensuring a stable supply of critical safety components such as brakes and functional parts like engine cooling and lubrication pumps.

We are committed to manufacturing that utilizes our long-cultivated casting and processing technologies, and are also focusing on the development of electrification solutions for the new era, aiming to contribute to a circular society. As a member of the international community, we consider it our social responsibility to respect human rights and not be complicit in any human rights violations.

We support and respect international norms such as the International Bill of Human Rights and the ILO Declaration on Fundamental Principles and Rights at Work, and have established the following policy in line with international guidelines such as the UN Guiding Principles on Business and Human Rights

1.Basic Stance

The TBK Group is committed to respecting internationally recognized human rights and to protecting and promoting them in all business activities. We declare to avoid any acts that infringe on human rights or may lead to such violations.

2.Scope of Application

This policy applies to all officers and employees of the TBK Group (including contracted employees, fixed-term employees, and temporary staff). We also expect our suppliers and business partners to share and comply with the principles of human rights respect.

3.Human Rights Due Diligence

We will periodically assess human rights risks and respond promptly to any identified issues. Additionally, we will implement risk mitigation measures as necessary.

4.Remedy and Correction

If any human rights violations occur, we will take appropriate remedial and corrective actions promptly.

5.Dialogue with Stakeholders

We will engage in regular dialogue with stakeholders and reflect their input in our human rights policies.

6.Information Disclosure

We will transparently disclose information on our human rights initiatives and progress through our website and other means on a regular basis.

7.Awareness and Education

We will ensure that all employees are made aware of this human rights policy and will provide regular training to promote understanding and awareness.

8.Legal Compliance

We will act in accordance not only with the laws and regulations of each country but also with international human rights standards, and comply with legal requirements regarding human rights risks in our business operations.

This policy has been approved by the Sustainability Committee, a body directly reporting to the Board of Directors, and has been signed by the President and Representative Director.

October 21, 2024

Kaoru Ogata

President and Representative DirectorTBK Co., Ltd.

Received the “Human Right Award” for Two Consecutive Years

TBKK (Thailand) Co., Ltd. has received the Human Right Award 2024 from the Ministry of Justice of the Kingdom of Thailand for the second consecutive year in recognition of its contributions to human rights initiatives.

The Ministry of Justice praised TBKK (Thailand) Co., Ltd. as a “model for other companies,” acknowledging its strong commitment to respecting human rights and contributing to the realization of a sustainable society.

The TBK Group will continue to uphold international human rights standards, contribute to the development of a sustainable society through its business activities, and promote responsible initiatives as members of a society where every employee walks together with mutual respect.