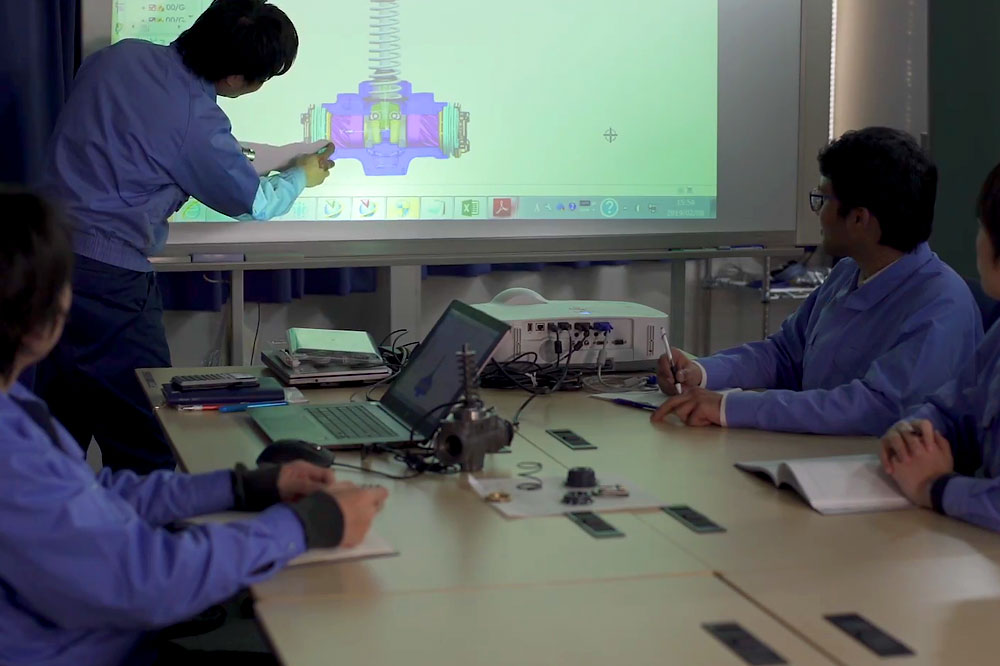

In the pump division, we contribute to the development efforts of engine manufacturers and vehicle manufacturers by pursuing lighter weight, higher efficiency, and quieter operation, as well as by developing electronically controlled energy-saving pumps that operate with minimal energy while maximizing engine performance.

As part of our commitment toward carbon neutrality, the new product development department promotes research and development to meet demands for new applications. Utilizing accumulated technologies in mechanical water pumps and oil pumps, we have realized the mass production of electric pumps and are also engaged in the development of thermal management systems for commercial vehicles centered on these core technologies.

In addition, to improve production efficiency and reduce costs, we consistently apply a design philosophy that considers parts standardization and process unification.

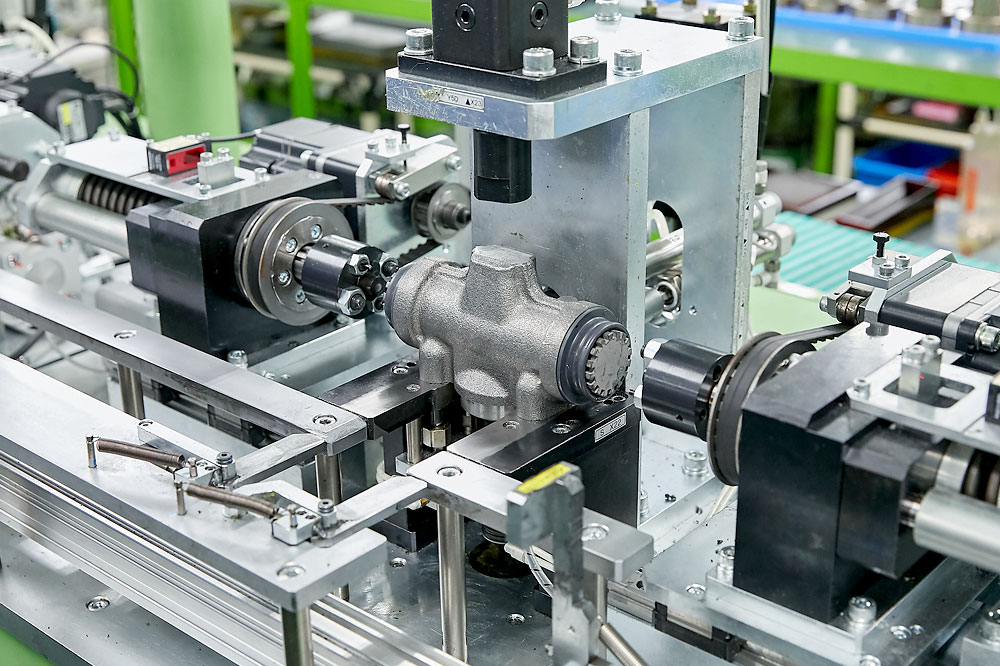

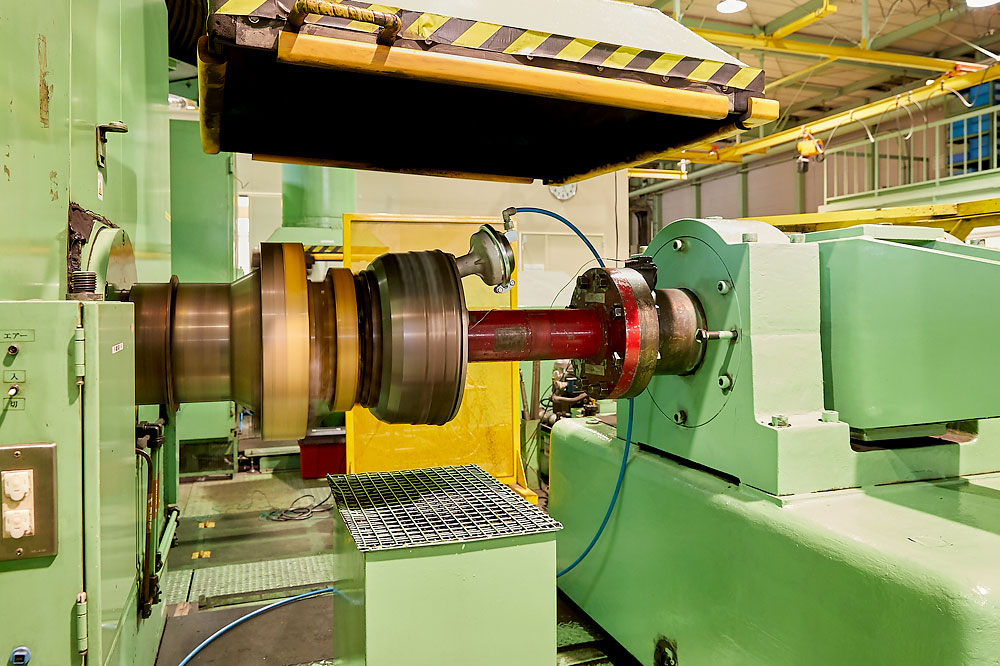

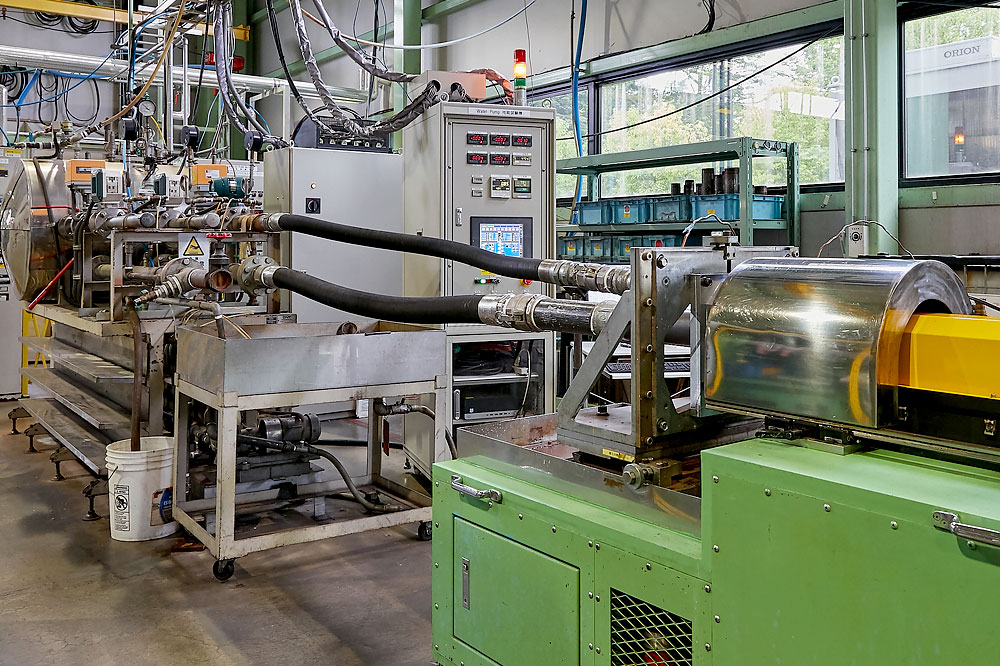

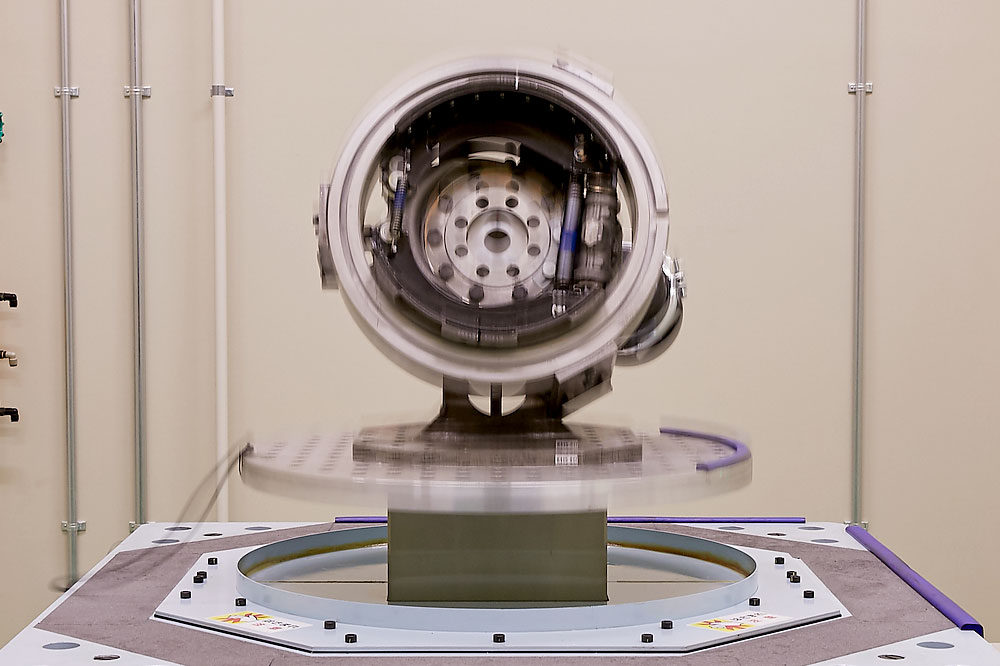

Before releasing new products to the market, we conduct rigorous performance and durability tests that simulate actual vehicle operation. In addition, we perform environmental tests such as temperature, humidity, water immersion, and vibration tests to ensure reliability.

(Testing conducted with cover attached)

In addition to numerous performance and durability tests on bench test machines, our company has a high-speed circuit that enables testing in various real vehicle environments, from low to high speeds. We conduct extensive real vehicle tests on this track.

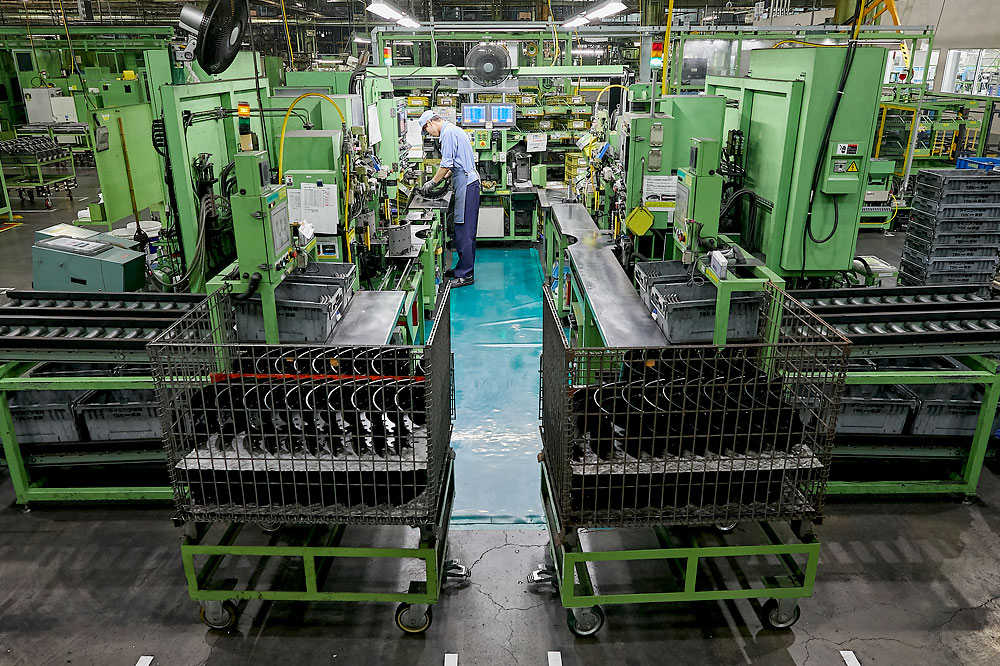

Our company has joined the NPS (THE NEW PRODUCTION SYSTEM) Study Group, an organization that supports Japan’s manufacturing industry. We actively learn the latest production management methods and industry best practices to further advance our unique production system, establishing a flexible and efficient production structure.

We inherit the TPS (TBK PRODUCTION SYSTEM) production philosophy previously adopted — “supplying what is needed, when it is needed, in the amount needed” — minimizing lead time, inventory, and input resources from raw materials to sales. Additionally, we achieve higher productivity and cost reductions through synchronized lines and mixed production lines for multiple product types developed in-house.

The NPS production method promotes manufacturing that achieves higher quality and productivity by thoroughly eliminating waste, based on the core principle of respect for people, beyond just-in-time and automation.